Bamboo for Cofiring

Bamboo biomass can replace coal, either partially or completely. When the coal is replaced partly with bamboo biomass, it is cofiring of coal and bamboo, that reduces the cost, CO2 emission, SOX and NOX emission.

Cofiring is sustainable and moves towards renewable energy. Bamboo biomass has good calorific value, very low ash content as compared to coal and optimum combustion property when fired along with coal. Cultivated bamboo as energy plantation and used at the age of one year, doesn’t have ash deposition issues, corrosion, pollutant emission and short supply of biomass fuel.

Cofiring biomass residues with coal in traditional coal-fired boilers for electricity production or in cement production, generally represents one of the most cost-effective and efficient renewable energy options for adoption of climate change technology, which doesn’t need additional investment.

Bamboo is grown as energy plantation under high planting density and harvested when the bamboo biomass is one year old. The harvested bamboo is chipped and dried as per the requirement of the boiler. Most of the boiler can accept 20% of biomass by weight for cofiring along with the coal. The cost of bamboo biomass is lower than the cost of coal, especially when it is cultivated as captive energy plantation.

Generally, the operation cost is typically higher for biomass then for coal. But in the case of Beema bamboo cultivation as energy crop, the cost of biomass is less and effectively reducing the operation cost apart from reducing the pollution.

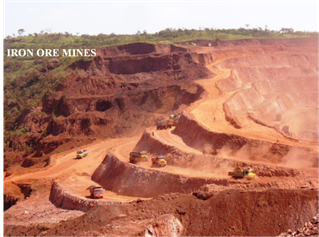

There are many power projects, cement manufacturing factories, mineral processing plant exploring the cofiring option. One must consider the existing boilers design and the firing process, to decide the percentage of bamboo biomass for cofiring. Similarly, based on the agroclimatic condition, soil test report, water test report, water availability, one must choose the right bamboo species and design the cultivation method.