Bio-CNG from Beema Bamboo

All parts of Bamboo are digestible to produce combustible gas. Bamboo biomass of 8 kg would produce 1 kg. of CNG gas and 4 kg. of dry undigested biomass having Lignin as major component. The gas is scrubbed and cleaned from carbon-di oxide, carbon monoxide and sulphur compounds. The processed biogas is compressed into bio-CNG and filled in dispensable gas cylinders. The undigested Lignin mass is converted into Briquettes/Pellets as by-products.

CNG is less polluting the environment than other popular fuel such as Petrol and Diesel. At present CNG is mostly delivered through pipes which are running for several thousand kilometres.

Bamboo is convertible into bio-gas which can be processed into Bio-CNG. Bio-CNG is a renewable fuel that is identical in composition and better in purity than fossil CNG. Bio-CNG from Bamboo generates income for the rural population and serves as an import substitute. Every 300 acres of cultivated bamboo can feed one gas bunk on the road side which does not need pipe lining for long distance. Bamboo based Bio-CNG can be produced locally everywhere, adjoining to the highways.

Agro Gas, a subsidiary of Primove Engineering Pvt. Ltd., Pune has tested Bamboo and established a model of Bio-CNG plant in Pune and functioning for the past 6 months. The technology is developed by Mr.Santhosh Gondlekar after several years of continuous research and hard work. This is the first Bio-CNG gas production and gas dispensing station in India.

Process:

Cultivation of Bamboo under hi-density:

Bamboo is planted under close spacing and harvested from 2 ½ years when it is grown as irrigated crop, with drip irrigation and fertigation. The plantation is established with fast growing thick wall Bamboo species with no thorns, with higher cellulose content. The Bamboo is harvested annually as immature bamboo and utilised for the production of Bio-CNG.

Conversion of Bamboo biomass into CNG:

All parts of Bamboo are collected from specifically grown in “Energy Plantation” and fermented with right combination of micro-organisms and bio-digested for 24 to 36 hours. The process generates bio-gas and biomass slurry.

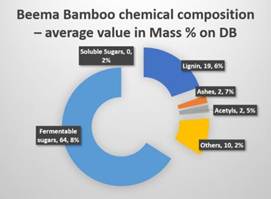

Bamboo biomass of 8 kg would produce 1 kg. of CNG gas and 4 kg. of dry undigested biomass having Lignin as major component. The gas is scrubbed and cleaned from carbon-di oxide, carbon monoxide and sulphur compounds. The processed biogas is compressed into bio-CNG and filled in dispensable gas cylinders. The Undigested Biomass mass is converted into briquettes/pellets as by-products.